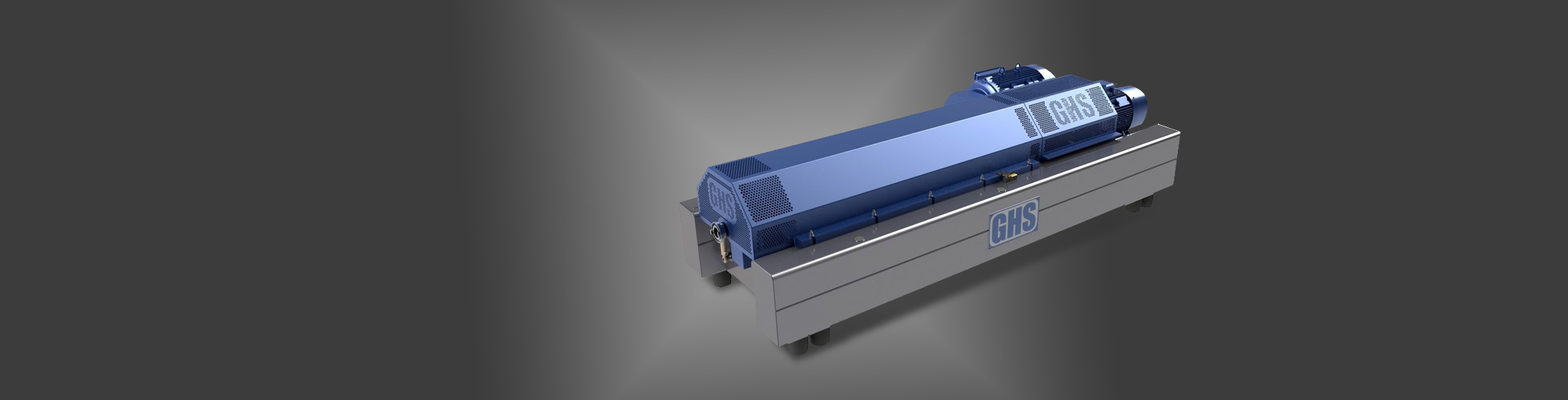

Centrifuges and decanters

Sewage sludge - sewage - mining - recycling

The separation technology of GHS includes high-speed centrifugal systems, which serve for the dehumidification of solids, clarification of media and the simultaneous separation of two or more liquids of different densities. GHS have a universal test bay for all rotor units with a diameter between 200 mm and 800 mm, with hydraulic or electric drive. All new industrial centrifuges, decanters and separators will be delivered with balanced rotors.

The advantages of our centrifugal separation technology:

| Model | Application |

| GHS | For organic, municipal and industrial applications |

| GHT | For mineral applications |

| GHO | For waste oil recycling |

| GHF | For the food and beverage industry |

All centrifuges and decanters are available in different diameters according to your individual application. You can choose from the following standard drum sizes:

GH-290

GH-390

GH-470

GH-530

GH-600

GH-820

Our specialists will also develop with you the right centrifuge size for your individual application.

GHS separators are designed for continuous separation of liquid mixtures. Use the centrifugal force takes place the separation of the media in a mechanical kind. Finest solid particles can thus be filtered through a high speed from a liquid.

Technical data:

GHD hydraulic drive - specially developed for the requirements of the customers - ensures a high operating safety of the centrifuge or the separator. Thanks to a new technology, the long service life is guaranteed, with low standstill and maintenance costs. The cover is optimized and balanced for a quiet and low-vibration operation. Different media, even with constantly changing solids content, can be processed without any difficults: The operation of the centrifuge is possible from the lowest differential speeds between 0 and 60 rpm. The drum and the rotor are controllable and are driven independently of each other. The scroll drive is motor driven. Thanks to this features the operation of the centrifuge is possible with low energy consumption and at low cost.

For the easy of operate of decanters and centrifuges withan electric or a hydraulic drive, we used a new generation of control systems. The control system is a special safety concept as well as a visualization of the most important functions on a single touch panel for easier and more user-friendly operation. The control of the centrifuge can be developed according to your needs on the basis of the experience gained from the practical operation in different application areas. Thanks to our special development, our separation systems have a washing program with stored parameter sets. The control system can also be retrofitted with older decanter centrifuges by our expert staff.