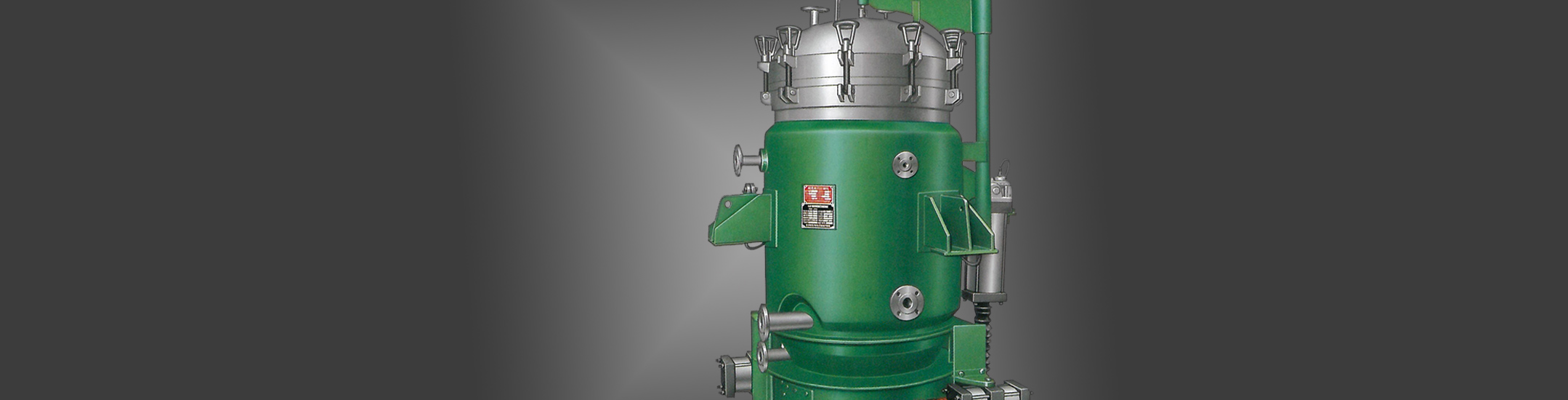

High Efficiency Plate Type

Hermetic Filter

High Efficiency Plate Type Hermetic Filter is a high-efficient, energy-Saving and hermeticalIy operated fine filter equipment. It is widely used in chemical, petroleum, panting, foodstuff, pharmaceutical and many other industries. This filter has many advantages such unique structure, compact volume, high filter efficiency, fineness of filtered liquor, no material wastage, without consumption of filter paper and filter cloth. It's only consuming small quantity of filter aid. It can be conveniently maintained, cleaned and operated at very low cost.

Technical data:

- Filtration area up to 90 m²

- Filter cake volume up to 1.800 l

- Treatment capacity up to 82 t/h

- Work pressure up to 0,5 Mpa

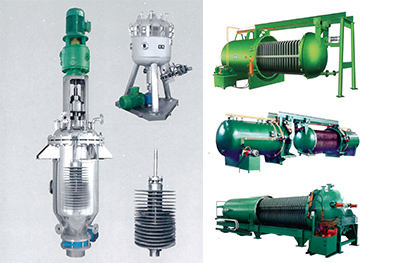

Self-cleaning filtering

core filter

The filtration ,adsorption and solid recovery of metal catalyzer, zeolite etc, in the industries of fine chemical, plastic, fuel electricity ,grease, lubricant, porcelain, glass,alkali etc. The self-cleaning filter is a kind of clarifying separation equipment with high-efficience, energy-saving and enclosed operation. It has traits as follows:

- Completely enclosed filtration no leakage, no pollution

- The filtering core adopts component structure which can be used widely and excellent filtering effect

- It can be thoroughly filtered onece

- Filter cake can be washed and dried in that it can achieve the best economical benefit.

- Adopting air blowing in reverse to discharge the residue which is rapid and clean, and also used in various sticky materials.

- The whole process can achieve completely full automatization.

Technical data:

- Filtration area up to 100 m²

- Shell diameter up to 1.800 mm

- Work pressure up to 0,5 Mpa

Automatic plate type hermetic filter

Automatic plate type hermetic filter is the fine clarifying and filtering equipment with high-efficiency and energy-saving. lt is widely used in chemical, petroleurn, food and pharmaceutical industry. With is unique structure, is has incomparable advantages:

- Fully hermetic filtering operation, no leakage, no pollution

- Once filtering complete clarified, its filtering precision up to ppm

- Low filtration cost and no need of filter paper and filer cloth

- Complete recovery, without residual filtrate

- The residue s easy to be automatically discharged, only pressing a controlled button

- Recovery the filtrate and the filtering residues together

- Combined with a computer, the whole filtering process are completely automate

- No limit of the filtering temperature less labor force and easy to operate

- Less cost of production and easy to repair and maintain

- The equipment had reached the advanced level in the world.

Technical data:

- Filtration area up to 35 m²

- Treatment capacity up to 29 t/h

- Work pressure up to 0,5 Mpa

Vertical and horizontal leaf filer

This flier is a fine clarifying filtrate equipment high-efficiency, energy-saving and auto hermetic. The leaf filer it has the following advantages:

- Fully hermetic filter, no leakage, no pollution

- As the eaves are designed In a horizontal disc form, cake can form stability which achieves good results

- The cake is spun out by centrifugal. It's very clean and quick. That's suitable to kinds of substance with different viscosity

- Filter gauzes are easy to wash and need not disassembly

- Small occupancy of the area, easy to operate

- The whole Process can be achieved automatically

- Applicable scope in liquid and solid separating in the filed of chemistry, drug, food, and so on, and the recovering, washing ,drying and reviving of catlyzer, etc.

Technical data:

- Filtration area up to 200 m²

- Shell diameter up to 2.000 mm

- Work pressure up to 0,4 Mpa

Multi-functions filtering, washing, drying (three-in-one) machine

GHS multi-functions filtering, washing, drying (three in one) machine is a solid-liquid equipment with the functions of filtration, washing, mixing reaction and residue discharging

automatically. It is widely used in chemical pesticide, petroleum foodstuff, printing, pharmaceutical industries and so on. It has the traits as follows:

- Fully enclosed filter, no leakage, no pollution

- Solid-liquid separation can be realized under pressure or vacuum state. Filter cake is evenly distributed when filtering which has good effect.

- Ascending and descending of the stirring system adopts hydraulic control, the filter cake and washing liquid can be fully mixed through going up and down of the stirring blade as well as stirring action, thus filter cake can be fully cleaned, the time ofdrying is reduced greatly, with high efficiency

- Discharging valve adopts hydraulic control that scrape dregs and discharge automatically, which can lower labor intensity

- Especially suitable for the material that with large solid content and recovering liquid phase and solid phase respectively

- Adopting filter material, Just as filter cloth, filter net, sintering net etc, one time completely filtering no remains. Filter material precision is available according to the requirements of product. Filter material has unique sealing structure which is easy to be changed

- Anticorrosion three in one system is made of special material which can be suitable for multiform anticorrosion medium

- Stirring, mixing, beating, reacting, washing and multiform process working can be practiced in the body and it can carry out full automatic control

Technical data:

- Filtration area up to 8 m²

- Shell diameter up to 3.200 mm

- Work pressure between -0,1 and 0,3 Mpa

Bag filter

Bag filter is a multifunction filter equipment with new structure, small occupancy, flexible operation, energy-saving, high- efficiency, enclosed operation and excellent applicability. The filter bag is mainly composed by filter cylinder, cylinder lid, quick-opening structure, filter bag reinforce net. The filter bag belongs to pressure filter equipment, liquid flow into the filter bag through the side-way. Filter bag itself is fitted in the reinforce net that the qualified filtrate is achieved after the liquid pass the filter bag which has various precision ranks. The impurity is seized by the filter bag The filter bag is easy to be changed and has litter consumption of materials. The dual parallel filter can increase the handling capacity.

Technical data (single filter):

- Filtration area up to 16 m²

- Treatment capacity up to 640 m²/h

- Work pressure up to 0,4 Mpa

Horizontal paper plate filter

Horizontal paper plate filter is a solid-liquid separating equipment with characteristics as high-efficienc, energy-saving, hermetic operating. It is widely used in chemical petroleum foodstuff, oils and fats pharmacy etc. The filter is composed of tank, layers of horizontal filter plates and filter paper which is installed between filter discs. Filter paper is used as filer medium to pressed filter in hermetic tank. During filtering, filtrate is conveyed to filter tank by pump and gets into middle of two filter plates from hole which are around the filter plates filtrate comes into hole of filter plate through filter paper and support plates and comes out from the bottom. After filter finished using compressed air to press the residual liquid out. This filter is a precision, clarification equipment. We can get filtrate with different precision through choosing filtering paper.

Technical data:

- Filtration area up to 15 m²

- Treatment capacity up to 18 t/h

- Work pressure up to 0,3 Mpa

Filtering core filters

The filters are accordant with the international standard. Its a kind of solid-liquid separation equipment with high-efficiency, energy-saving, enclosed operation and precision clarification. The traits are unique structure, compact size, easy to assemble the filtering core and clean the filter cylinder conveniently. The filter is composed of several filtering cores installed upright in the enclosed cylinder. Compressed filtering was made in the cylinder that depends on filtering cores as the filter medium.

Technical data:

- Shell diameter up to 600 mm

- Work pressure up to 0,4 Mpa

Rotary pressure filter

Rotary pressure filter is a new shape solid-liquid separation equipment and integrating filtrate, washing, drying, automatic discharging and continuous, automatic cleaning. The equipment with innovative structure and has following unique characteristics.

- Under the pressure or vacuum state, the equipment can achieve to continuous solid-liquid separation, several times washing the cake, drying the cake, automatic discharge the cake and cleaning the filtering medium.

- The whole process will be operated hermetically, no environmental pollution.

- The whole process can be operated variable speed control according to the material properties.

- The filter cake thickness can be adjusted according to the process requirement.

- With high production efficiencyand low use cost.

- Occupy little area and simple operation.

- Long service life and maintenance cycle of equipment, easy to repair.

- The whole process can be automated.

Technical data:

Filtration area up to 7,68 m²